The inspection of castings mainly includes dimensional inspection, visual inspection of appearance and surface, chemical composition analysis and mechanical property test. For castings with high requirements, non-destructive testing is also required. For example, non-destructive testing techniques for quality inspection of ductile iron castings include liquid penetrant testing, eddy current testing, magnetic particle testing, radiographic testing, and ultrasonic testing.

Testings of Surface and Near-Surface Defects of Castings

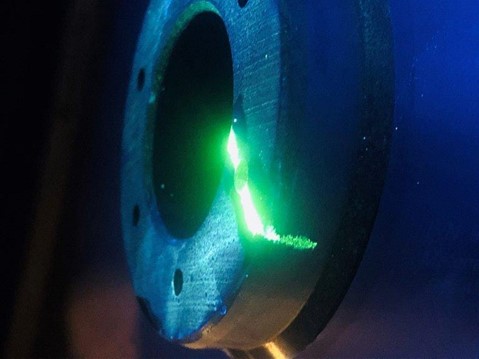

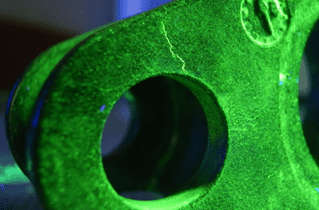

Liquid Penetrant Testing

Liquid penetrant testing is used to inspect various opening defects on the surface of castings, such as surface cracks, surface pinholes, and other defects that are difficult to find by naked eyes.

The commonly used penetrant testing is dye testing, which is to wet or spray the high permeability penetrant on the casting surface, infiltrate the penetrant into the opening defects, quickly wipe off the penetrant layer, and then spray the easy to dry developer on the casting surface. After the penetrant which remains in the opening defects is sucked out, the developer will be dyed, so as to reflect the shape, size, and distribution of the defects.

It is pointed out that the smoother the surface to be tested, the better the effect of penetration testing. The surface polished by the grinder comes with the highest testing accuracy, and even intergranular cracks can be detected.

In addition to dye testing, fluorescent penetrant testing is also a commonly used liquid penetrant testing method. It needs to be equipped with an ultraviolet lamp for irradiation observation, and the testing sensitivity is higher than the dye testing.

Eddy Current Testing

Eddy current testing is suitable for testing defects below the surface that are generally not more than 6-7MM deep. Eddy current testing is divided into two types: the placed-type coil method and the through-type coil method.

When the test piece is placed near the coil with alternating current, the alternating magnetic field entering the test piece can induce eddy current flowing in the direction perpendicular to the excitation magnetic field in the test piece. Eddy current will produce a magnetic field opposite to the direction of the excitation magnetic field, which will partially reduce the original magnetic field in the coil, resulting in the change of coil impedance.

If there are defects on the casting surface, the electrical characteristics of the eddy current will be distorted, so as to detect the existence of defects. The main disadvantages of eddy current testing are that it can not directly display the size and shape of the detected defects. Generally, it can only determine the surface position and depth of the defects. In addition, its sensitivity to the testing of small opening defects on the casting surface is not as sensitive as the penetrant testing.

Magnetic Particle Testing

Magnetic particle testing is suitable for testing surface defects and defects several millimeters deep below the surface. It requires DC (or AC) magnetization equipment and magnetic particle (or magnetic suspension liquid) for testing.

Magnetization equipment is used to generate a magnetic field on the inner and outer surfaces of the casting, and magnetic particle or magnetic suspension liquid is used to reveal defects. When a magnetic field is generated within a certain range of the casting, the defects in the magnetized area will generate a leakage magnetic field. When the magnetic particle or suspension liquid is sprinkled, the magnetic particle is attracted, so that the defects can be displayed.

The defects revealed by magnetic particle testing are basically those that transverse the magnetic line of force, but the long strip defects parallel to the magnetic line of force cannot be displayed. Therefore, it is necessary to constantly change the magnetization direction during operation to ensure that each defect in the unknown direction can be tested.

Testings of Internal Defects of Castings

For internal defects, the commonly used non-destructive testing methods are radiographic testing and ultrasonic testing. Among them, the effect of radiographic testing is the best. It can get an intuitive image reflecting the type, shape, size, and distribution of internal defects. However, for thicker large castings, ultrasonic testing is very effective, which can accurately measure the location, equivalent size, and distribution of internal defects.

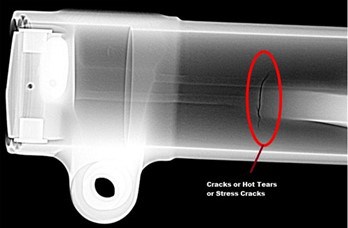

Radiographic Testing

Radiographic testing, generally X-Ray or γ-Ray as the ray source, the ray generating equipment and other auxiliary facilities are needed. When the casting is exposed to the ray field, the radiation intensity of the ray will be affected by the internal defects of the casting. The radiation intensity emitted through the casting varies locally with the size and nature of the defects, forming a radiographic image of the defects, which is imaged and recorded by radiographic film.

The method of recording by radiographic film imaging is the most commonly used method, which is commonly referred to as radiographic testing. The defect image reflected by radiography is intuitive, and the shape, size, quantity, plane position and distribution range of defects can be presented.

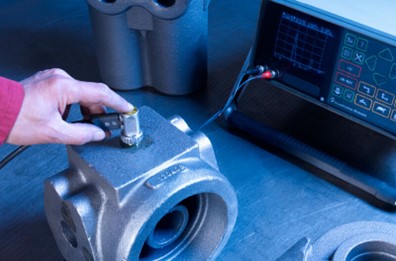

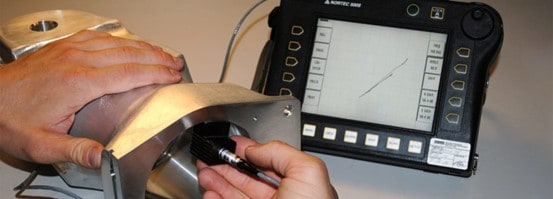

Ultrasonic Testing

Ultrasonic testing uses the propagation of sound beams with high-frequency sound energy inside the casting to generate reflections when they hit the inner surfaces or defects. The magnitude of the reflected acoustic energy is a function of the directivity and properties of the inner surfaces or defects and the acoustic impedance of such a reflector. The acoustic energy reflected from various defects or inner surfaces can thus be applied to detect the location of the defects, the wall thickness, or the depth of the defects below the surface.

As a widely used non-destructive testing method, ultrasonic testing comes with the main advantages: high testing sensitivity, which can test small cracks; large penetrating ability, which can detect thick section castings. Its main limitations are: difficult to interpret reflection waveforms for discontinuous defects with complex contour dimensions and poor directivity; undesirable internal structures, such as grain size, microstructure, porosity, inclusion content, or finely dispersed precipitates, also hinder the waveform interpretation.