Casting

Metal liquid forming, or casting usually refers to the machining way that pouring liquid metal into a casting cavity suitable for the shape and size of the part, and then cooled and solidified to obtain the blank or part.

Technological Process

Liquid metal-mold filling-solidifying contraction-casting parts

Technological Characteristics:

• Parts with complex shape can be manufactured, especially the parts whose entocoele is complicated.

• High adaptation. There is nearly no limitation of alloy type and parts’ size.

• Wide raw material source, recycle casting waste and low investment in equipment.

• High waste rate, poor surface quality and bad working conditions.

Casting classification

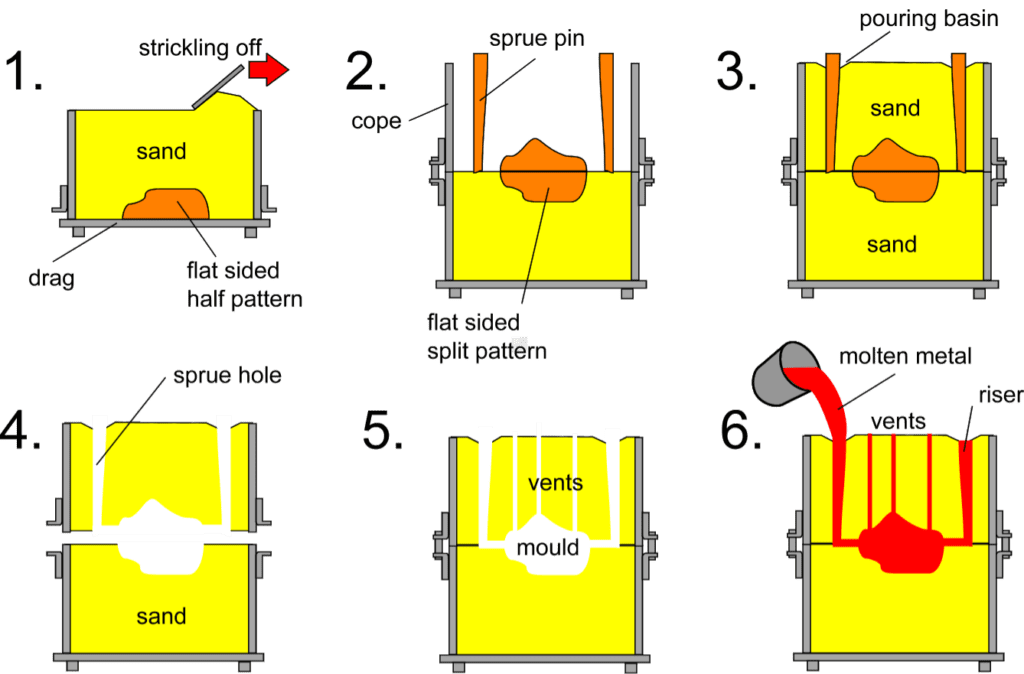

Sand Casting

It refers to the casting way in which the parts manufactured from sand mold. It is widely used in steel, iron, and most non-ferrous alloy castings.

Sand Casting Technological Process

Sand Casting Technological Characteristics

• It is suitable for the workblanks that have complex shape, especially complex entocoele.

• Wide adaptation and low cost.

• For some bad plasticity material (like cast iron), sand casting is the only way to make related part or workblank.

Sand Casting Application

Automobile engine block, cylinder head, crankshaft and other castings.

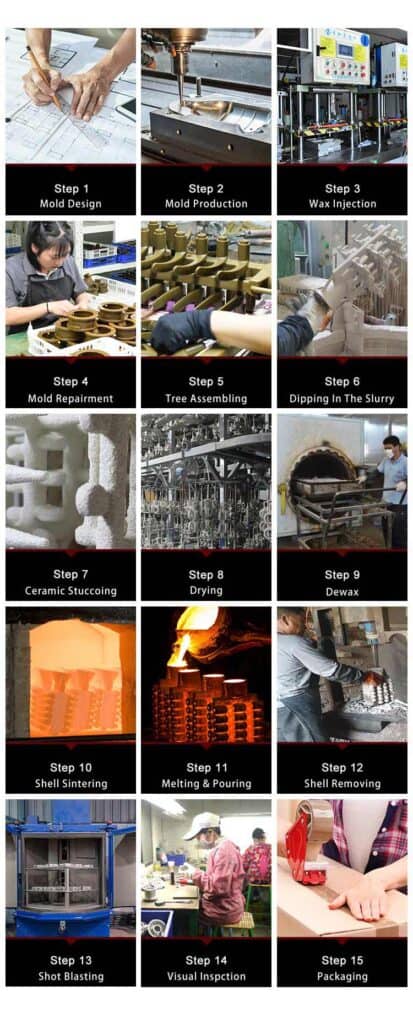

Investment Casting

Investment casting usually refers to the casting method in which the shape is made of fusible materials, and the shape surface is coated with a number of layers of refractory material to make a shell.

Then the shape is melted and discharged from the shell, so as to obtain the casting without parting surface, and the sand can be filled after high temperature roasting.

Sand Casting Technological Process

Investment Casting Technological Characteristics

Advantages

• High dimension and geometry precision.

• High surface roughness.

• Complex shape castings can be made and the raw material casting alloy is unlimited.

Disadvantages

Complicated working procedure and high cost.

Application

Lost-wax casting is suitable for those parts that need complex shape, high precision requirements, or other small casting parts which can only be done via investment casting, such as turbine engine blades, etc.

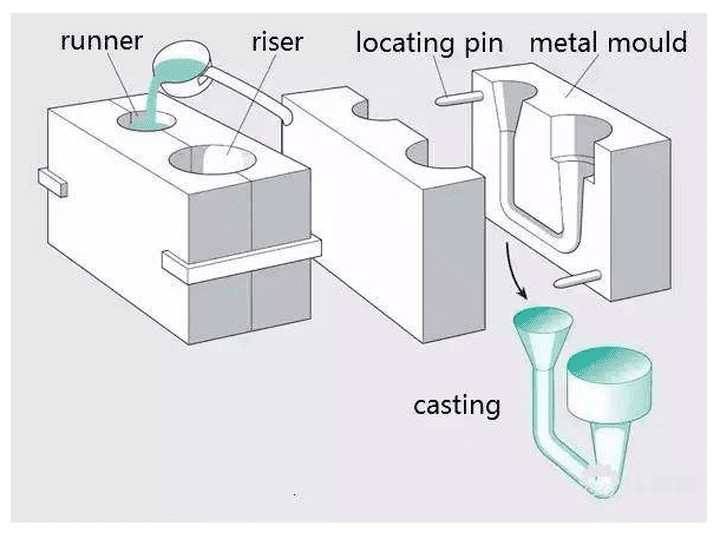

Die Casting

Die Casting Technological Characteristics

advantages

• Liquid metal bears high pressure and the flow rate is fast during die casting.

• Good product quality, stable dimension and good exchangeability.

• High production efficiency and recycle die casting molds.

• Mass production preference and good economic returns.

disadvantages

• Die casting parts is easily to produce tint stomata and porosity.

• Die castings have low plasticity and are not suitable to work under load and vibration conditions.

• The die casting life of high melting point alloy is low, which affects the expansion of die casting production.

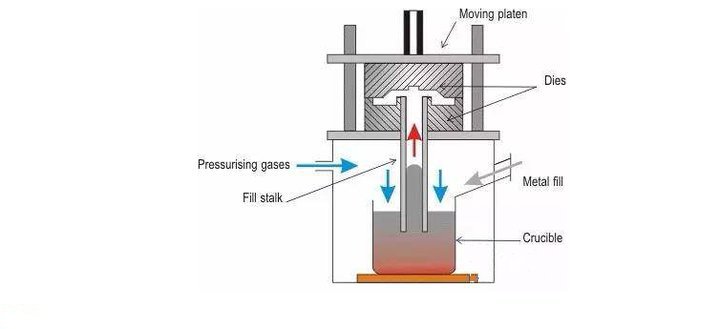

Low Pressure Casting

It is a method of filling the casting mold with liquid metal under low pressure (0.02 ~ 0.06mpa) and crystallizing under pressure to form the casting.

Low Pressure Casting Technological Process

Low Pressure Casting Technological Characteristics

• The pressure and speed of casting can be adjusted, so it can be applied to all kinds of different casting mold (such as metal mold, sand mold, etc.), casting all kinds of alloy and castings of all sizes.

• The casting crystallizes under pressure.Dense casting structure, clear outline, smooth surface, and high mechanical properties are beneficial for the castings, especially the large thin-walled parts.

• Leave out feeding head, and the metal utilization rate can increase to 90 ~ 98%.

• Low labor intensity, good working conditions, simple equipment, and easy to realize mechanization and automation.

Application

Low pressure casting usually applied in traditional products, such as Cylinder head, wheel hub and cylinder rack.

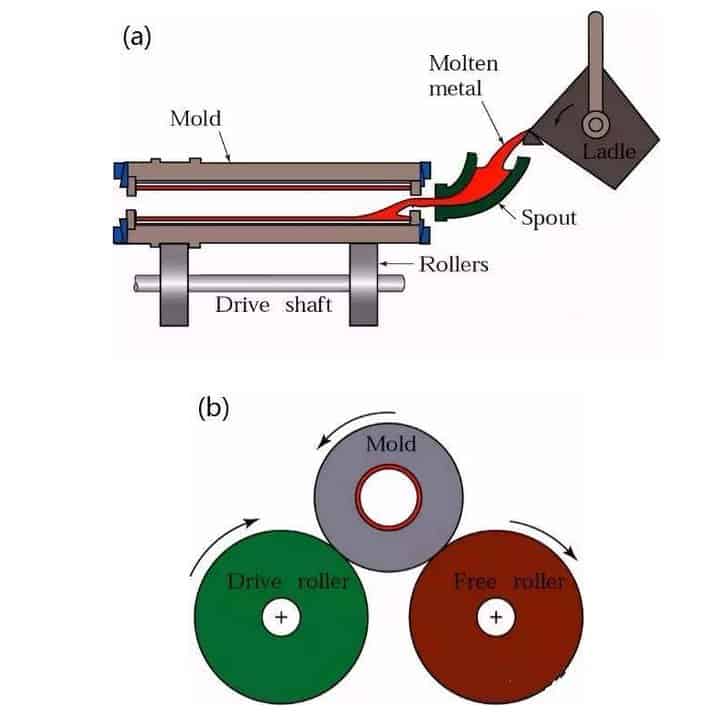

Centrifugal Casting

It is a casting method that the metal liquid is poured into the rotating casting mold and filled with the casting mold and solidified under the action of centrifugal force.

Centrifugal Casting Technological Process

Centrifugal Casting Technological Characteristics

Advantages

• There is nearly no metal consumption of gating system and riser system. The process yield is greatly increased.

• There is no necessary to use the mold core in hollow castings production. As a result, the metal filling capacity can be greatly improved in the production of long tubular castings.

• The casting has higher density, lower porosity, slag and other defects, and higher mechanical properties.

• Easy to manufacture composite metal castings like cylinder and sleeve.

Disadvantages

• There is limits in profiled castings production.

• The diameter of the inner hole of the casting is not accurate, the surface is rough, the quality is poor, and the machining allowance is large.

• Centrifugal Casting is easy to produce specific gravity segregation.

Centrifugal Casting Application

Centrifugal casting was first used in the production of cast pipes. It is used in in metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automobile and other industries to produce steel, iron and non-iron carbon alloy castings. Cast iron pipe, internal combustion engine cylinder liner and shaft sleeve casting production is the most common.

Vacuum Die Casting:

Advanced die casting process that eliminates or significantly reduces air holes and dissolved gases in die castings by removing gases in die casting cavities during die casting, thereby improving mechanical properties and surface quality of die castings.

Technological Characteristics:

Vacuum Die Casting advantages:

• Eliminate or reduce the air holes in die casting, improve the mechanical properties and surface quality of die casting, and improve the coating performance.

• To reduce the back pressure of the cavity, the alloy with lower specific pressure and poor casting performance can be used. It is possible to die cast larger castings with small machines.

• The filling conditions are improved and thinner castings can be die cast.

Vacuum Die Casting disadvantages:

• Complex mold structure and hard manufacture & setup makes high cost.

• If vacuum die casting does not controlled well, the effective will be barely satisfactory.

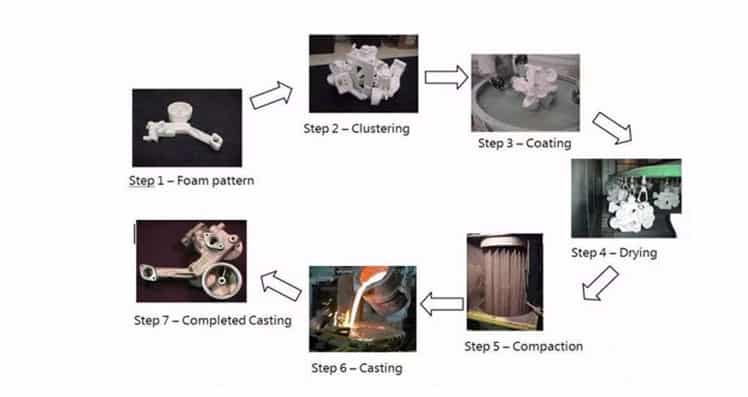

Lost foam casting(cavity casting):

.jpg)

It is a new type casting that bind the paraffin wax or foam model, which have similar size and shape as castings, into clusters. Brush fire-proof coating and dry it, bury it in the dry quartz sand and vibrate the model.

Under the negative pressure casting, the model will gasify, liquid metal takes model’s place, and finally the casting will be made after cooling solidification.

Technological Characteristics:

• High casting precision, no sand core which reduced production time.

• No parting surface, flexible design, high degree of freedom

• Clean production and no pollution.

• Reduced investment and production cost.

Lost foam casting Application:

Suitable for various sizes of precision castings with complex structure, no limit on alloy type and production batch.Such as gray cast iron engine box, and high manganese steel elbow.

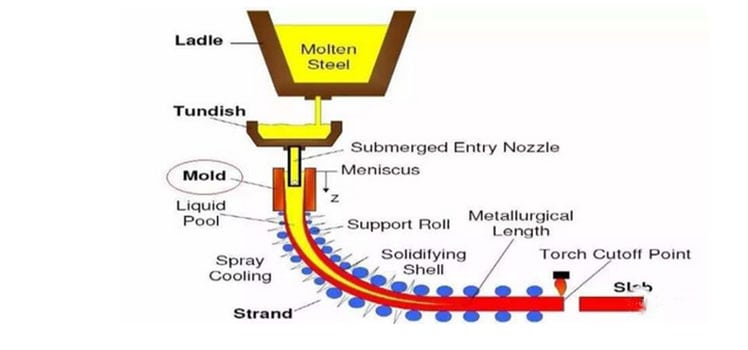

continual casting:

It is an advanced casting method in which molten metal is poured continuously into a special metal mold called a mold. The solidified (crusted) casting is continuously pulled from the other end of the mold to obtain a casting of any length or a specified length.

Technological Characteristics:

• Good mechanical properties due to the rapid cooling of the metal, compact crystal, and uniform structure.

• Metal save, and yield improved.

• Labour intensity hereby reduced for process simplified, modeling and other processes exempted.

• Continuous casting helps mechanism and automation accomplish and production efficiency boost.

continual casting Application:

Continuous casting can be used to long castings with invariable shape, in steel, iron, copper alloy, aluminum alloy, magnesium alloy, such as ingot, slab, bar billet, pipe, etc.