Stainless steel investment casting process

Some stainless steel products with complex structures are not able to be manufactured by bending and other processings, while we can choose the investment casting

Some stainless steel products with complex structures are not able to be manufactured by bending and other processings, while we can choose the investment casting

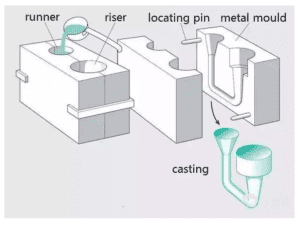

Metal liquid forming, or casting usually refers to the machining way that pouring liquid metal into a casting cavity suitable for the shape and size of the part, and then cooled and solidified to obtain the blank or part.

In the manufacturing industry, especially in key industries such as aviation, aerospace, national defense, and automobile, the basic core components are generally metal parts, and a considerable number of metal parts are asymmetric, irregular curved surfaces or parts with complex structure and fine structure…

The investment casting process refers to making a model with wax, wrapping a layer of refractory materials such as clay on the surface, heating the wax to melt and flow out, so as to obtain an empty shell formed by the refractory material.

The stainless steel investment casting industry is different from the traditional casting industry. Although China is already the country with the largest casting volume in the world, investment casting is still in the development stage, and there is still a big gap with developed countries.

Investment casting is one of the centuries-old metal manufacturing processes, which can date back 5,000 years. In its earliest forms, beeswax was used to form patterns necessary for the casting process. Today, more advanced waxes, refractory materials, and specialist alloys are typically used for making patterns.Molten metal is poured into a consumable mold formed by refractory ceramic material with a wax pattern involved. The wax is melted out and the molten metal will solidify inside the ceramic mold, and then the metal casting parts hatch out. That’s why investment casting is often referred to as “lost-wax casting”.

Precision forming of metal products Making objects out of metal involves many manufacturing processes. One of these is machining, a necessary requirement of mass manufacture

Lost wax, one-time molds create precision products with finer surfaces What is investment casting? Investment casting, often referred to as “lost-wax” casting, uses an expendable-mold