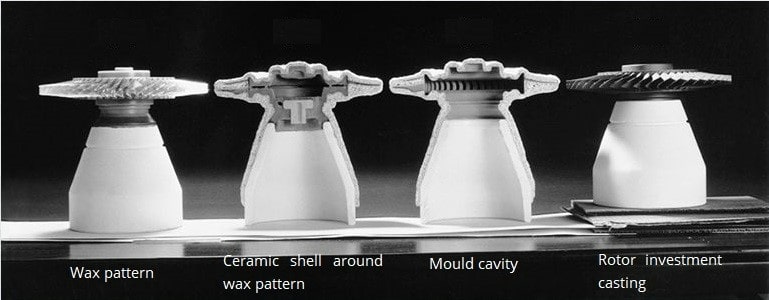

Investment casting is one of the centuries-old metal manufacturing processes, which can date back 5,000 years. In its earliest forms, beeswax was used to form patterns necessary for the casting process. Today, more advanced waxes, refractory materials, and specialist alloys are typically used for making patterns.Molten metal is poured into a consumable mold formed by refractory ceramic material with a wax pattern involved. The wax is melted out and the molten metal will solidify inside the ceramic mold, and then the metal casting parts hatch out. That’s why investment casting is often referred to as “lost-wax casting”(More content reference: What is Investment Casting?).

Investment casting is so named because the process invests (surrounds) the pattern with refractory material to make a mold, and a molten substance is cast into the mold. Most of the metals can be manufactured by metal investment casting, such as aluminum alloys, brass, copper alloys, bronze alloys, steel alloys, cast iron, stainless steel.

The cavity inside the refractory mold is an exact duplicate of the desired part.Due to the hardness of refractory materials used, the lost wax casting process normally generates complex high precision parts with an excellent surface finish, such as turbine blades or firearm components. High-temperature applications are also common, which includes parts for the automotive, aircraft, and military industries. Sometimes investment casting can also reduce or even eliminate the necessity for machining,which is often the only way a part could be manufactured economically.

Water glass and silica sol investment casting are the two primary investment casting methods nowadays. The main differences are the surface roughness and cost of casting. The water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. The silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold. The silica sol method costs more but has a better surface than the water glass method.Precise Cast offers both silica sol investment casting and water glass casting as options for our clients in different industries, covering various weight of casting components.

We can produce top-level investment castings in a variety of dimensions and shapes. In our foundry, the investment casting process is operated with the most advanced technology in China. In the whole process, all-metal alloys are available, we can customize investment castings according to your material specifications.

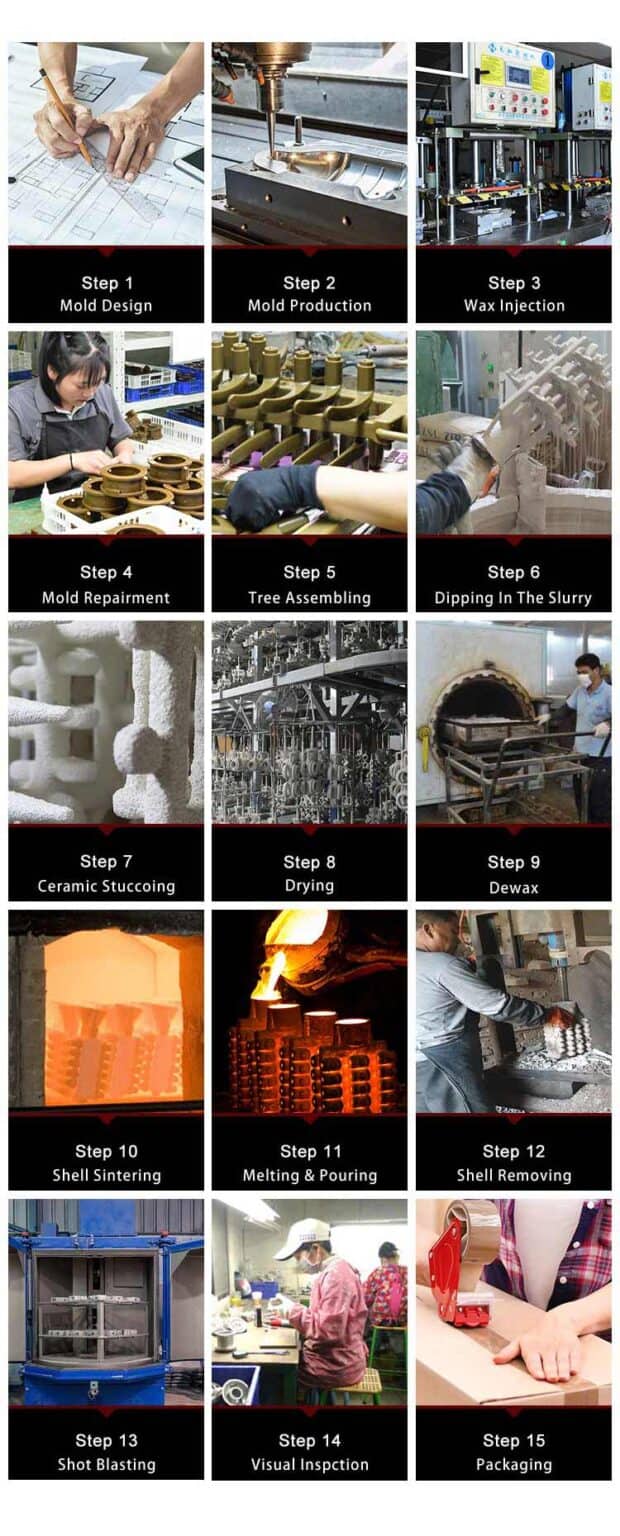

It is the first step for the metal investment casting process, the basis to achieve precision products, and also the basic step to make wax patterns.Precise Cast has world-class CNC machining centers to produce high-precision casting mold and offer rapid tooling service for our clients.

A pattern that duplicates the finished part geometries is made by two primary methods:

Make a wax injection die: The wax pattern is obtained by injecting wax into the pattern. We will get a model with the same dimensions as desired products. Then, we will repeat the injection job for more wax patterns

3D printed wax pattern

After wax patterns are finished, they will be assembled into runners, then into a finished tree which is ready to be dipped.

After the slurry coating is done, sand particles are dropped onto the surface of the wet tree assembly, which helps to thicken and strengthen the layer of coating on the wax assembly surface.

The wax inside the newly built shell is now removed by putting the shell in a steam-dewaxing autoclave or flash fire furnace. The wax will be melt and run out through the gate and pouring up under high temperature.The ceramic shell molds must be fired to burn out the last traces of pattern material and then preheat the mold in preparation for casting. Usually in the range of 1600-2000 degrees Fahrenheit, that is why investment casting also called “lost wax casting”.

The molten metal is poured into the preheated mold cavities. Casting or pouring is the key step in the whole investment casting process.

The mold then sits to allow the molten metal to cool and solidify at room temperature, which then becomes the final castings.

The shell material is then removed through processes like hammer knockout, vibration, or steel grit blasting.

The finished casting parts are then cut free from the sprue and runner system, and then remove the excess metal from the casting body by grinding.

Various finishing techniques are then employed including heat treatment, grinding, polishing, shot blasting/sandblasting, and coating to achieve the final requested surface.

Heat Treatment: The Heat Treatment process can improve the mechanical properties of casting blanks. The main heat treatment processes are Normalizing, tempering, annealing, hardening, and tempering, carburizing.

Shot Blasting/Sandblasting: To remove scales and achieve a better surface finish, investment castings will be shot blasted or sandblasted by small steel balls.

Anti-rust Oil Painting & Surface Treatments: In order to avoid rusting, castings will be dipped into anti-rust water or oil. The other surface treatments can also be performed in this step like paint spraying, galvanizing.

Inspection is also one of the most important steps for investment casting parts quality control. Once the finishing operations are done, the parts are inspected according to technical drawings and requirements. Visual and fluorescent penetrant inspection is done for surfaces and X-ray is applied for sub-surface defect identification.

Investment casting is beneficial for casting metals with high melting points. Due to all sorts of products that investment casting can produce, it has universal industry applications.

Parts that are typically produced by investment casting technology include those with complex structures such as turbine blades or firearm components (firearm receivers, triggers, and hammers). Investment castings are even used by beverage industry equipment manufacturers and international pressure relief valve manufacturers in the oil and gas industry. Investment casting parts are also widely used in the aerospace, medical, jewelry, automotive, aircraft, and military industries.

Components manufactured by the investment casting process also result in products like dental fixtures, gears, cams, ratchets, jewelry, machinery components, and other parts of complex geometry. As a result, it’s safe to say that regardless of your industry, if your business can benefit from the advantages of investment cast parts and components, they might be the perfect metal option for any and all of your projects.

| Equipment Name | Quantity | Average Service Time |

|---|---|---|

| Wax Injection Machine | 30 sets | 4 years |

| Vibratory Polishing Machine | 12 sets | 3 years |

| Water Welder | 3 sets | 3 years |

| Welding Machine | 15 sets | 4 years |

| Broaching Machine | 2 sets | 5 years |

| Heat Treatment Furnace | 2 sets | 5 years |

| Polishing & Buffing Stand | 50 sets | 4 years |

| Sandblasting Machine | 15 sets | 8 years |

| Sintering Furnace | 9 sets | 8 years |

| Washing Machine | 10 sets | 8 years |

| Swiss Type CNC Auto Lathe | 20 sets | 4 years |

| CNC Lathes | 30 sets | 5 years |

| CNC Machine Center | 25 sets | 4 years |

| Tapping & Drilling Units | 80 sets | 6 years |

You will get better service at Precise Cast, as we can meet all your unique rapid prototype investment casting needs. We can constantly and consistently supply rapid prototype & production service, striving our best to make your design ideas a reality. If you have specific requirements for prototype investment castings, please request a quote to know more.